Since its inception, Marsh Industries, Inc. has specialized in the extrusion of silicone rubber products for the lighting, appliance and aerospace industries, as well as for processing aids in the second and third tier automotive industry. We can manufacture extrusions to your specifications and can assist you in developing a product design that best suits your needs.

Since its inception, Marsh Industries, Inc. has specialized in the extrusion of silicone rubber products for the lighting, appliance and aerospace industries, as well as for processing aids in the second and third tier automotive industry. We can manufacture extrusions to your specifications and can assist you in developing a product design that best suits your needs.

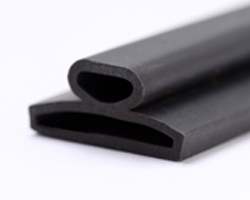

In the extrusion process, silicone rubber is extruded to make such products as tubing, solid rods, profile gaskets, seals and preforms used in compression molding. The silicone compound is continuously forced through a die that forms it to the desired cross-sectional size and shape. After the extrusion process, the silicone is vulcanized and cured.

Marsh Industries’ extrusions are fabricated into gaskets bonded endless, “picture frame” gaskets with 45 degree corners, or are cut to length. Most profiles can be supplied in bulk footage.

Marsh Industries’ extrusions are fabricated into gaskets bonded endless, “picture frame” gaskets with 45 degree corners, or are cut to length. Most profiles can be supplied in bulk footage.

Marsh Industries, Inc. has the available capacity to meet all of your extrusion needs.

Our EDM capabilities enable us to produce extrusion dies of varying complexity with precision, and in a timely manner. For the customer, this means a much faster turnaround time for both prototype as well as production run extrusions. Equipped with six production extrusion lines and a total of four HAV (hot air vulcanizing) horizontal and vertical curing systems, Marsh Industries, Inc. has the available capacity to meet all of your extrusion needs. Whether you require 100 feet, 100,000 feet, or even higher footage, Marsh Industries can extrude to meet low and high volume runs to satisfy customer demand.

Our EDM capabilities enable us to produce extrusion dies of varying complexity with precision, and in a timely manner. For the customer, this means a much faster turnaround time for both prototype as well as production run extrusions. Equipped with six production extrusion lines and a total of four HAV (hot air vulcanizing) horizontal and vertical curing systems, Marsh Industries, Inc. has the available capacity to meet all of your extrusion needs. Whether you require 100 feet, 100,000 feet, or even higher footage, Marsh Industries can extrude to meet low and high volume runs to satisfy customer demand.